NEWS

Catch up on the latest intouch news!

Read the latest news about intouch.

Intouch Monitoring to showcase innovative MES solution at NPE 2024 – The Plastics Show

Orlando, Florida – April 4, 2024 – Intouch Monitoring, a leading provider of production monitoring…

Intouch reflects on the great success of 2023!

Following a brilliant 2022, the Intouch team celebrate another successful year as 2023 draws to a…

Intouch Monitoring sponsors Moulton charity Halloween Spooktacular event

This year sees the 9th anniversary of the Moulton Spooktacular charity event in the village of…

Intouch Monitoring named a finalist in the prestigious Plastics Industry awards 2023

Intouch Monitoring a leading innovator in production monitoring software, is thrilled to announce…

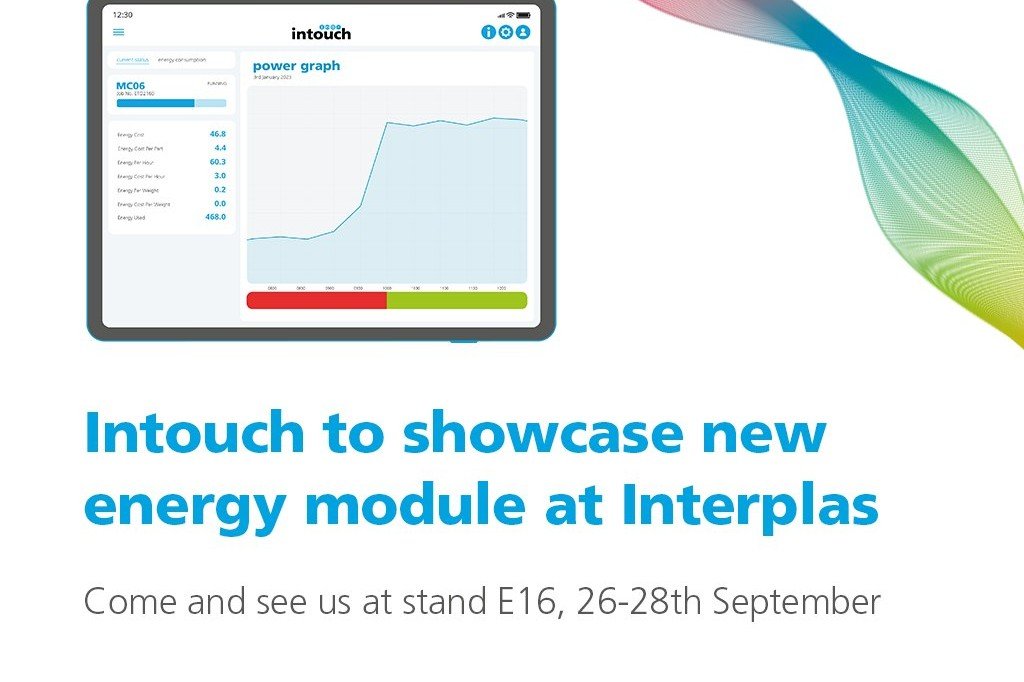

Intouch to showcase how new energy module achieves over 30% reduction in energy consumption at Interplas 2023

Intouch Monitoring, a pioneering leader in production monitoring software, is excited to unveil the…

PlastikCity visits the Intouch HQ for ‘PlastikCity on Tour’

Will Clarke and Jess Clarke from PlastikCity visit the Intouch office as part of their 'PlastikCity…

Russell Roof Tiles Invests in Intouch Production Monitoring System

Russell Roof Tiles recently invested in new technology to streamline its manufacturing. See the…

Intouch launches new real-time energy waste alert module

Intouch Monitoring, a pioneering leader in Production Monitoring Software announces their…

Intouch celebrates another successful year – 2022 Highlights

In 2022, we experienced a number of exciting milestones. From getting the chance to meet many new…

New Free Trial Launch

Work with our team to find out how Intouch can maximise your efficiency and increase profitability…

Ready to increase your productivity?

We would love to hear from you. Call, email or use the contact form and we’ll get right back to you.

Headquarters

Intouch Monitoring Ltd

1 Airways House

Sywell Aerodrome

Northamptonshire

NN6 0BN